Elevator Hydraulic Oil: Oil changes, upgrades, and maintenance

Key Highlights

- Regular elevator hydraulic oil changes are vital for smooth and safe elevator operation.

- Ignoring oil changes can lead to costly repairs and downtime.

- Several signs indicate the need for an oil change, such as unusual noises or slow operation.

- Choosing the correct type of hydraulic oil is crucial for optimal performance.

- Consulting a qualified elevator professional is recommended for all oil changes and maintenance.

- Upgrading your system with an oil cooler can significantly improve performance and longevity.

Introduction

In the world of moving between floors, hydraulic elevators are dependable helpers. They move both people and things easily. At the center of these elevators is hydraulic fluid. This fluid is key for smooth and good operation. The power unit pumps and controls this fluid. It is very important for how well the elevator works and how long it lasts. Like any machine, regular upkeep is important. Paying close attention to the hydraulic fluid helps stop problems and keeps everything working well.

Understanding Elevator Hydraulic Oil Basics

Hydraulic elevators use a simple and effective method. The power unit pumps hydraulic fluid into a cylinder. This action pushes a piston, which then moves the elevator cab. The hydraulic fluid is specially made for hydraulic applications. It is not just a lubricant; it also helps transmit force. Keeping the fluid clean and of good quality is very important. It helps prevent wear and tear on the system's parts, which can make the system last longer.

Over time, the hydraulic fluid breaks down. This can happen because of heat, dirt, and oxidation. When it degrades, its performance goes down. This causes the system to work less efficiently and use more energy. It can even lead to damage in the system.

The Importance of Oil Quality in Hydraulic Elevators

The performance of a hydraulic elevator depends a lot on the quality of the hydraulic oil used. Good quality oil is made for hydraulic applications and has important additives. These additives help stop corrosion, oxidation, and wear. They keep the oil thick enough and slippery, which helps the elevator run smoothly and reduces friction in moving parts.

On the other hand, if you use bad-quality or dirty oil, it can hurt the elevator's performance. More friction can waste energy and cause overheating. This can also make parts like pumps, valves, and seals wear out faster. You will then see higher maintenance costs, more downtime, and a shorter life for the whole hydraulic system.

So, it is really important to use high-quality hydraulic oil designed for elevators. It’s also essential to follow the manufacturer's guidelines and check the oil regularly. These steps will help keep the elevator system running well, lasting longer, and being safe.

Types of Hydraulic Oils Used in Elevators

Selecting the right type of hydraulic oil is paramount for optimal performance. Factors like viscosity, additives, and environmental considerations come into play.

Consult your elevator manufacturer or a qualified technician to determine the most suitable oil type for your specific elevator system, considering factors like elevator type, usage patterns, and environmental conditions. For instance, twin jack holeless elevators with multi-stage telescopic jacks might require different oil specifications compared to standard hydraulic elevators.

Comprehensive Guide to Elevator Hydraulic Oil Changes

Changing the hydraulic oil in your elevator is important, just like changing the oil in your car. If you ignore this maintenance task, it can cause problems. You might see less performance, more expensive repairs, and even safety risks.

To keep your hydraulic elevator system working well, you need to know when to change the hydraulic oil. Following a clear plan is key. Regular maintenance and quick responses to warning signs will help keep your elevator running safely and smoothly.

Signs Your Elevator Needs an Oil Change

- Unusual Noises: If you hear grinding, screeching, or whining sounds, this might mean that the hydraulic oil is not lubricating well.

- Slow Operation: When the elevator feels slow or takes more time to level, it could mean that the hydraulic fluid is losing its thickness and ability to work properly.

- Jerky Movements: If the elevator moves unevenly or feels bumpy, this might show that the hydraulic oil is dirty or not working right.

- Overheating: If you feel excessive heat coming from the power unit, this might mean the oil is breaking down. This can cause more friction and less efficiency.

- Oil Discoloration: If you see dark or cloudy oil in the reservoir and it smells burnt, this is a clear sign of serious oil breakdown and contamination.

Step-by-Step Process for Changing Elevator Hydraulic Oil

While it's best to hire a skilled elevator technician for this job, knowing the steps can help.

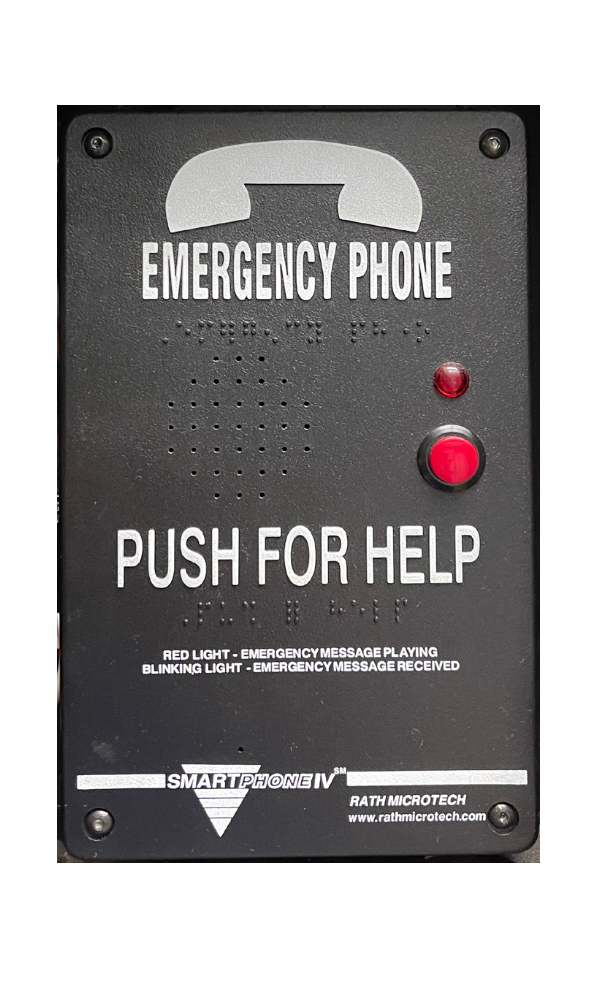

- Safety First: Turn off the power to the elevator. Make sure to follow the right lockout/tagout steps.

- Drain the Oil: Find the drain valve on the reservoir. Drain the old hydraulic oil into a safe container.

- Flush the System: Follow the instructions from the manufacturer to flush the system. This may need a special flushing fluid to clear out leftover contaminants.

- Replace Filters: Put in new hydraulic oil filters based on the manufacturer’s guidelines.

- Refill with Fresh Oil: Add the right type and amount of hydraulic oil to the reservoir. Be sure to check the oil levels carefully.

- Bleed the System: Release any trapped air in the system by bleeding it from the right valves.

Conclusion

Elevator hydraulic oil is important for elevators to work properly. Knowing the basics and types of oils, along with the need for quality oil, helps in maintenance. You need to change the oil regularly to avoid problems and keep the elevator safe. Following simple steps to change the oil can help your elevator last longer. Keep an eye out for signs that it's time for an oil change. Good maintenance will make your elevator work better and be safer. If you have questions about hydraulic oil, check our FAQ section or ask for expert help.

Frequently Asked Questions

How often should hydraulic oil be changed in elevators?

The number of times you need to change the hydraulic oil depends on different things. These include how often you use the elevator, the conditions around it, and the advice from the manufacturer. Generally, most hydraulic elevators need an oil change every 3 to 5 years. Elevators that have high usage, face extreme temperatures, or carry heavy loads may need oil changes more often. This helps to prevent early wear and tear on the power unit and keeps the elevator working well. It’s a good idea to talk to your elevator maintenance provider. They can help you create a maintenance schedule that fits your elevator's needs.