Elevator Pit Basics: What You Need to Know

Key Highlights

- The elevator pit is a crucial component of elevator systems, providing a space for safety equipment and maintenance access.

- Water intrusion is a serious concern in elevator pits and can be mitigated with proper waterproofing techniques.

- Pit dimensions and specifications are regulated by building codes to ensure safety and accessibility.

- Regular inspections and maintenance are essential for keeping the elevator pit in optimal condition.

- Understanding the basics of elevator pits is vital for building owners and managers to ensure safety and compliance.

- By prioritizing elevator pit maintenance, building owners can prevent costly repairs and downtime.

Introduction

The elevator pit is an important part of vertical transportation. It is usually not seen because it is under the ground floor. This area plays a key role in making sure elevators work safely and well. The elevator pit is the space at the bottom of the elevator shaft, going below the ground floor level. It serves as a base for the elevator system. The pit contains important equipment and helps keep people safe from possible dangers.

Understanding Elevator Pits

The elevator pit is an important part of every elevator system. It serves as the base and provides safety. This area is located underground and holds essential parts that help the elevator run smoothly. In a way, it is the main support for the entire elevator system.

Besides being a strong structure, the elevator pit is key for safety as well. It has equipment that helps prevent fast movements, softens any falls, and helps during emergencies. Keeping this area checked and maintained is very important to make sure the elevator system stays safe and works well for a long time.

The Role and Functionality of Elevator Pits

Elevator pits play an important role in how elevators work and stay safe. They hold equipment like sump pumps that help manage water intrusion. Since these pits are below ground, they can get wet. This helps protect the elevator car and electrical parts from damage, allowing the elevator to run smoothly.

In addition, the pits have safety devices. These include buffers or bumpers that reduce shock if the elevator car goes too high. They are a crucial safety feature that helps lower the chance of injury or damage during unexpected events.

Finally, elevator pits are key areas for maintenance workers. Technicians can use this space to check, fix, and take care of different elevator parts. This helps keep the system reliable and ensures it meets safety rules.

Comparing Traction and Hydraulic Elevator Pits

Traction elevators are common in tall buildings. They use steel ropes and a counterweight system to operate. In their pits, you will find important equipment like overspeed governors and tail sheaves, which help keep things safe.

On the other hand, hydraulic elevators are usually found in shorter buildings. They work with a hydraulic piston and cylinder system. In their pits, they have a hydraulic reservoir, pump, and valves. This setup needs special care to contain oil properly.

The main difference between the two is in how they lift. Traction elevators depend on ropes and counterweights. In contrast, hydraulic elevators use a hydraulic piston to lift the elevator car. This leads to different designs and equipment in their pits.

Design and Specifications

When designing elevator pits, following building codes and safety standards is very important. These rules define what is needed for pit size, strength, ease of access, and safety features. This helps keep both passengers and maintenance workers safe.

Also, things like the type of elevator, how much weight it can hold, and how the building is used greatly affect the design and size of the pit. Carefully studying these factors during the design stage is essential. This ensures the pit can support the elevator system properly and meets all safety regulations.

Key Dimensions for Elevator Pits

The dimensions of an elevator pit are crucial and vary based on factors like elevator type and building codes.

Pit Depth: 8-10 feet

Pit Length & Width: Typically a minimum of 8 feet by 8 feet

These dimensions ensure sufficient space for housing necessary elevator equipment, like buffers and sump pumps, while also allowing safe access for inspection and maintenance. Neglecting these specifications can compromise safety and result in code violations.

Safety and Accessibility Considerations

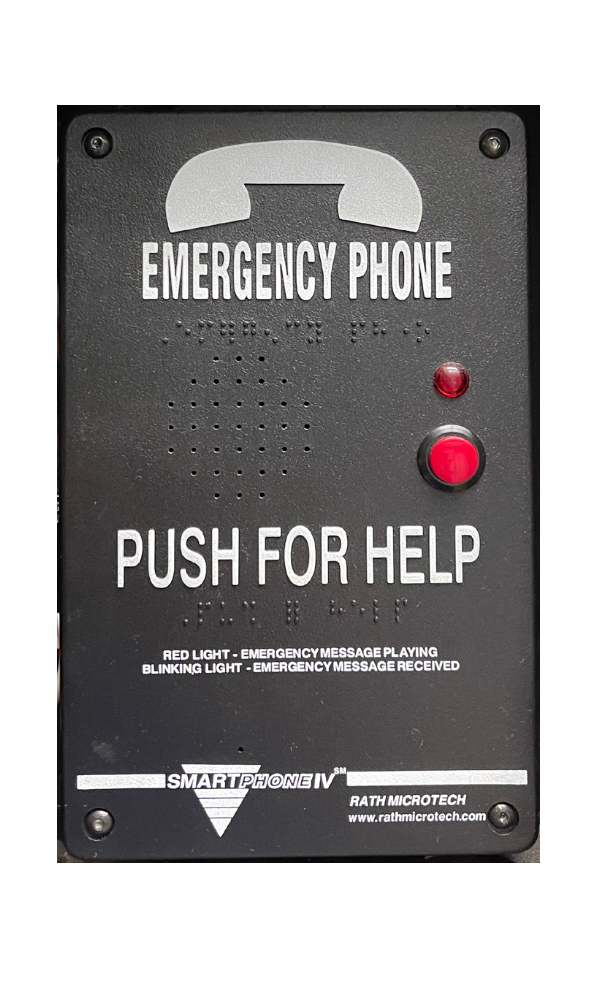

Safety in the elevator pit is very important and involves several measures. Toe guards are put in place at the landing edge. They help stop objects from falling into the pit and harming people underneath. It is also critical to deal with water problems. The pit floor should be sloped properly, and good drainage systems and sump pumps are needed. These help to reduce the chance of flooding from surface water sources or plumbing leaks. Lastly, the way to access the pit is planned carefully. Usually, there is a secure access door at the lowest landing of the shaft. This door has safety switches that turn off the elevator when it's open. This keeps maintenance workers safe.

Conclusion

Elevator pits are very important for how elevators work and for keeping them safe. It's important to know how they are designed, their sizes, and how to maintain them so they perform well. If you're using traction or hydraulic systems, you should think about waterproofing and how easy it is to get to them. Regular upkeep and following safety rules are needed for safe operation. When you're updating or planning new elevator pits, focus on safety, strength, and following the rules. By keeping yourself updated and taking action, you can improve how well elevators work and how long they last. Knowing these basics helps keep everything running smoothly and keeps passengers safe.

Frequently Asked Questions

Why is waterproofing essential for elevator pits?

Waterproofing is very important for elevator pits. These pits can easily get water due to different reasons. This includes water from the ground, leaks from plumbing, and rainwater runoff. If a good waterproof membrane is not put on the walls of the pit, water may build up. This can harm electrical parts, cause rust, and result in expensive repairs and downtime for the elevator.

Can elevator pits be retrofitted for better performance?

Yes, elevator pits in older buildings can be upgraded to work better and be safer. This can mean updating the sump pump system, using new waterproofing material, or improving lighting and airflow. These elevator maintenance tasks can fix current problems and stop new ones from happening.

What are common maintenance tips for elevator pits?

Regular elevator maintenance is very important for elevator pits. This means you should check for any signs of water intrusion. You also need to make sure that drain tile systems are clear and working well. Checking the sump pump is key too. Keeping the pit clean and free of debris helps avoid hazards and makes sure the elevator works its best.

How do elevator pit dimensions impact the overall design?

The size of the elevator pit is important for the design of the elevator system. The area of the pit floor shows how much space is there for parts like buffers and controllers. The depth of the pit affects how far the elevator car can move, which helps with the system's speed and works well. So, it is very important to carefully think about these sizes during the design phase to make sure everything works great.

What are the legal requirements for elevator pits in the US?

Legal rules for elevator pits in the US can change based on the state and local area. Building owners need to follow the rules in their local code. These rules usually include things like the size of the pit, the materials used for building it, waterproofing, and safety features. For instance, San Francisco may have tougher rules about earthquakes than other places.