Elevator Pressure Test: A Comprehensive Guide

Key Highlights

- Elevator pressure tests are essential for ensuring the safe operation of elevators and compliance with safety regulations.

- This test assesses the functionality of the pressure relief valve in hydraulic elevators.

- During the test, the elevator is loaded to its maximum weight capacity to evaluate its performance under stress.

- Regular pressure tests help identify potential issues early on, preventing costly repairs and downtime.

- Building owners and facility managers are responsible for scheduling regular pressure tests and maintaining accurate records.

Introduction

Elevator testing is very important for keeping elevators safe and working well. One key test is the elevator pressure test. This test checks how well critical safety systems are working. This guide will explain elevator pressure tests in detail. It will provide helpful information for building owners, facility managers, and anyone working in elevator maintenance.

Understanding Elevator Pressure Tests

An elevator pressure test is a special check done on hydraulic elevators. This test makes sure the safety parts, especially the pressure relief valve, work well. The pressure relief valve is important. It stops the elevator from getting too much pressure, which could cause unsafe situations.

Hydraulic elevators are different from traction elevators. Traction elevators use ropes and counterweights to move up and down. In contrast, hydraulic elevators use a hydraulic system to lift the elevator cab. The pressure relief valve serves as a safety feature in this system.

Defining Elevator Pressure Testing

Elevator pressure testing, also known as elevator load test or load testing, focuses on the pressure relief valve in a hydraulic elevator system. This valve helps release extra pressure if the system is overloaded. This feature stops possible damage or accidents.

During a pressure test, skilled technicians create an overload situation to check if the pressure relief valve works correctly. They slowly increase the pressure in the hydraulic system and watch the pressure gauge during the test.

If the valve activates within the safe limits, the test is successful. However, if the valve does not activate or activates incorrectly, it shows there is a problem. Quick action is needed to ensure the elevator stays safe.

The Importance of Regular Elevator Pressure Tests

Regular pressure tests for elevators are very important for keeping hydraulic elevator systems safe and reliable. Doing these tests every year helps qualified elevator service workers find potential issues before they become bigger problems.

When technicians test the pressure relief valve in a controlled way, they can see how it works and make sure it will work properly in case of an overload. Regular testing helps stop dangerous situations. Too much pressure can cause parts to fail, leading to fast descents or other risks.

Following a regular elevator pressure test schedule also helps meet safety rules and industry standards. Building owners and managers show they care about the safety of passengers and lower their risk of legal problems by putting these tests first.

Preparing for an Elevator Pressure Test

Proper preparation is key for a smooth pressure test of the elevator. You need to schedule the test with a qualified elevator service company. Be sure to give them access to the elevator equipment and necessary documents. It's also important to inform the building occupants about the test and any possible disruptions in elevator service.

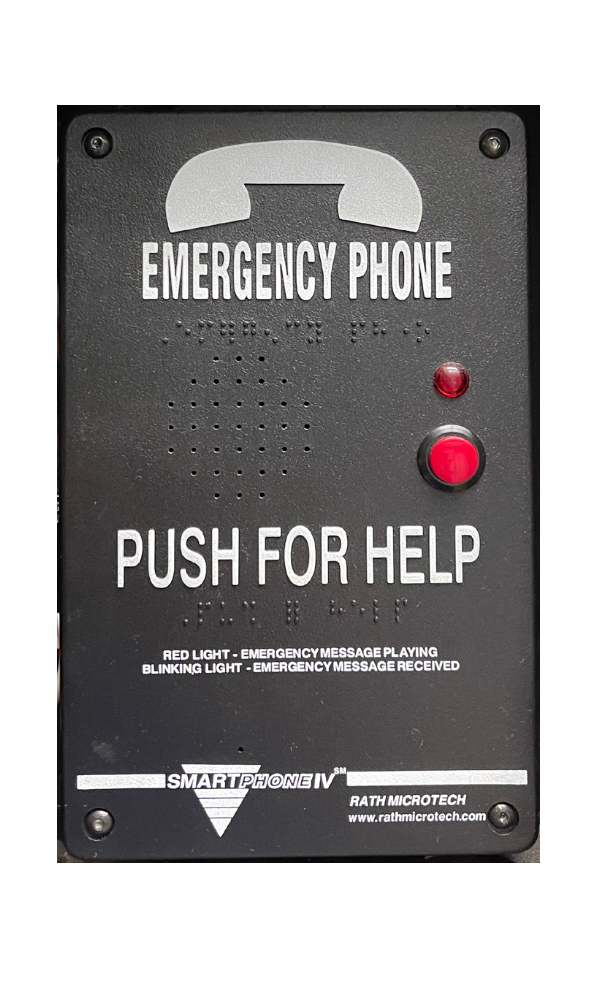

Before the technicians arrive, make sure the elevator is safe to test. This means fixing any known problems and checking that all safety features, like emergency brakes and communication systems, are working well.

Necessary Tools and Equipment

Elevator technicians use special tools and equipment to perform elevator pressure tests that are accurate and reliable. These tools help control and check the pressure of the hydraulic system during the tests.

One important tool is a certified pressure gauge. This gauge precisely measures the pressure levels inside the hydraulic system. Technicians use it to watch how pressure changes as they add load to the system. They also use hydraulic jacks or pumps to slowly raise the pressure in the system to mimic an overload situation.

Other necessary tools include wrenches for getting to hydraulic parts, safety glasses and gloves for protection, and voltage meters to check that electrical parts are working correctly. It is crucial for technicians to have these tools and equipment available. This ensures they can conduct the tests safely and efficiently.

Safety Protocols and Precautions

Safety is very important during elevator pressure tests. The elevator industry follows strict safety rules to avoid accidents and protect both workers and building residents. Facility managers and elevator service companies need to work closely to follow these rules carefully.

Before any tests start, technicians create a safe area around the elevator to stop unauthorized people from entering. They also turn off the elevator so no one can use it during the tests. Signs and barriers help show where the restricted area is.

During the tests, technicians stay alert. They keep a close eye on pressure levels and how the elevator is working. They are ready to use emergency shutdown procedures right away if any unexpected problems or safety issues come up.

The Elevator Pressure Test Process

The elevator pressure test is a careful process. It checks how well the pressure relief valve works. Skilled elevator technicians perform this test, making sure to follow good safety rules and industry standards.

The test starts with a full inspection of the elevator system. This includes looking at the hydraulic pump, the motor, and the pressure relief valve. After the inspection, technicians hook up a certified pressure gauge to the hydraulic system. This gauge helps them measure any changes in pressure during the test.

Before starting the test, they ensure all safety measures are in place. They also keep the elevator closed to the public. Then, the technicians can carry out the pressure test safely.

Step-by-Step Guide to Conducting the Test

Conducting an elevator pressure test requires a clear step-by-step plan to make sure everything is safe and accurate:

- Preparation: Before starting the test, technicians make sure the elevator is closed to the public. This way, no one can call or use it. They also check that the emergency communication system in the elevator is working.

- Load Simulation: For a "full load test," technicians simulate the weight of a fully loaded elevator car. They do this by filling the car with weights or using special hydraulic jacks to apply pressure on the system, mimicking the maximum load.

- Pressure Monitoring: Once the load is in place, the technicians turn on the hydraulic system and closely watch the pressure gauge. They carefully write down the pressure shown when the relief valve opens.

During the test, technicians follow strict safety rules. They are ready to shut down the system right away if anything unusual happens.

Interpreting Test Results

Once the elevator pressure test is complete, interpreting the test results is essential to determine the system's functionality and compliance with safety standards. The primary focus is on the pressure at which the relief valve activated during the test.

The test results are compared against the manufacturer's specifications for the specific elevator model and its rated weight capacity. If the relief valve activated within the acceptable range outlined by the manufacturer, the elevator passes the test.

In situations where the test results fall outside the acceptable range, further investigation may be necessary.

Conclusion

Regular pressure tests on elevators are very important. They help keep elevators safe and working well. By following safety rules, using the right tools, and doing tests correctly, you can find problems early on. Knowing how to test elevator pressure and reading the test results is helpful to avoid accidents and keep elevators running smoothly. It is also key to maintain elevators often and do pressure tests. This keeps you following the rules and makes sure everyone is safe. Stay on top of things to stay safe.

Frequently Asked Questions

How often should elevator pressure tests be conducted?

Most service contracts suggest doing annual pressure testing for routine elevator maintenance. This helps to keep the safety systems working well. However, local rules and recommendations can vary based on the age of the elevator and codes specific to the area.

What are the common issues identified during an elevator pressure test?

Common problems discovered during elevator pressure testing include a pressure relief valve that does not work, goes off at the wrong pressure, or appears rusty or damaged. Fixing these issues with quick elevator service helps keep the elevator safe to use at its maximum load capacity.

Can an elevator still operate safely if it fails a pressure test?

An elevator cannot run safely if it does not pass a pressure test. When it fails, this shows that there is a problem with important safety systems. This problem is usually due to a faulty pressure relief valve. Elevator technicians need to fix the issue before the elevator can be used again.