Elevator Installation Process: A Comprehensive Overview

Key Highlights

- Installing an elevator is a complex process involving various steps, from site preparation to final testing and handover.

- Careful planning is crucial, including choosing the right elevator system, assessing building requirements, and obtaining necessary permits.

- Adhering to safety standards and building codes throughout the process is non-negotiable.

- Working with experienced professionals ensures a smooth installation that meets all safety and functionality requirements.

- Regular maintenance and inspections are mandatory after installation to ensure the elevator operates safely and efficiently for years to come.

Introduction

Elevators are important for modern buildings. They help people move up and down safely and quickly. Putting in an elevator is a complicated job. It needs careful planning. You must know the building’s needs and follow safety standards. You will also need to work with local authorities to get the necessary permits. This guide will help you understand the key steps in an elevator installation project. It will cover everything from beginning to end. Regular maintenance is also very important for keeping the lift running well and making sure users are safe.

Understanding the Basics of Elevator Installation

Elevator installation is not just about putting a lift in a building. It is a careful process that requires knowledge of building codes, safety rules, and the technical details of these systems. The installation process can change a bit depending on the type of elevator, the layout of the building, and specific needs.

The process starts with checking the building in detail. This includes looking at its layout, strength, and how it will be used. Next, people decide on the best type of elevator and its capacity. They also choose the best spot for the elevator shaft.

The Importance of Elevators in Modern Buildings

In today's city scene, tall buildings are everywhere, and elevators have become a must-have instead of a nice extra. Modern buildings, especially commercial buildings, depend a lot on elevators. They help people and goods move easily between different floors.

Elevators are very important for accessibility. They help people with mobility challenges get around the building without problems. Also, elevators play a key role in moving heavy equipment and materials between floors in commercial buildings.

Key Components of an Elevator System

An elevator system has many parts that work together to help people and goods move up and down safely. The main part is the elevator car. This is the closed platform that takes passengers or freight. The elevator car moves on guide rails inside a tall space called the hoistway or elevator shaft.

The power to lift and lower the car comes from the elevator machine. This machine can work in two ways: hydraulic or traction. The control system directs the elevator's movements. It takes care of how fast the elevator goes, which way it moves, and when the doors open or close. This helps give everyone a smooth ride.

Preparing for Elevator Installation

Before the installation starts, some important steps need to happen first. This begins with a full check of the building and what it needs. Next, we must get the necessary permits. Let’s look at these steps closely.

Good preparation is key for a successful elevator installation. By paying attention to these pre-installation tasks, we can reduce problems during the installation process. This helps things go smoothly and makes the work easier.

Assessing Building Requirements and Elevator Types

The first step to get ready for elevator installation is to look at what the building needs. You should think about things like the building's height, how many floors there are, the number of people expected to use the elevator, and any accessibility needs.

After figuring this out, you can choose the right type of elevator. For example, hydraulic elevators work well for low-rise buildings. In contrast, taller buildings usually need traction elevators. Picking the right type of elevator at the beginning helps use space well and ensures good performance.

By understanding the specific needs of the building, you can select the best elevator system. This choice helps the elevator fit in smoothly with how the building is designed and functions.

Necessary Permits and Regulations in the United States

Elevator installations in the United States are subject to various codes and regulations to ensure safety and compliance. Local authorities typically require building permits and adherence to specific elevator codes.

Building Permit: This permit authorizes the construction of the elevator shaft and any necessary structural modifications to the building.

Electrical Permit: Required for the installation of the elevator's electrical systems, including wiring, control panels, and safety devices.

Mechanical Permit: This permit covers the installation of the elevator's mechanical components, such as the machine, hoistway equipment, and safety features.

Working closely with local authorities throughout the permitting process is crucial, ensuring the elevator installation meets all safety and code requirements.

Step-by-Step Guide to Elevator Installation

With all the needed preparations, the real installation can start. This usually has different stages. Each stage needs special skills and keeping to safety rules.

Now, let’s look closely at each stage of the installation process. This will help understand the details and challenges involved.

Step 1: Site Preparation and Safety Measures

The first step in elevator installation is preparing the site. This means making a safe and organized area for work. The team needs to clear the space where the elevator will go. They must also ensure easy access for tools and workers.

Next, it is very important to have strong safety measures during the whole process. Before starting work, the team checks the area carefully. They find and fix any possible dangers. This includes making sure the area is safe, adding good lighting, and using measures to prevent falls.

By following strict safety steps, the installation team can get the site ready. This helps to make the installation smooth and efficient.

Step 2: Installing the Guide Rails and Hoistway

With the site ready, the next step is to put in the elevator's guide rails and hoistway. The hoistway is the vertical space that holds the elevator car and its counterweights.

Installing the guide rails needs careful work. You must take exact measurements and make sure everything is lined up right. These rails help guide the elevator car as it moves up and down, making its movement smooth and stable.

The whole process of installing the guide rails and hoistway needs skilled workers and special equipment. It is important to make sure the hoistway is straight, level, and aligned properly. This is essential for the elevator's safe and reliable operation.

Step 3: Setting Up the Elevator Car and Machine Room

This stage focuses on putting the elevator car in the hoistway and setting up the machine room. The machine room is the center of the elevator system. First, the elevator car is carefully lowered into the hoistway and attached to the guide rails.

The machine room has the elevator's driving parts and is usually above the hoistway. It's important to make sure the machine room has:

- Enough space for the equipment

- Enough overhead clearance for maintenance

- Proper ventilation to stop overheating

It's very important to connect the elevator car to the hoist ropes or hydraulic system correctly to ensure safe operation. The installation and connection of the elevator car are done with great care, using special tools and methods.

Step 4: Electrical Wiring and Control Systems

Once the mechanical parts are set, it's time to start the electrical part of the installation. This step includes:

- Running electrical wiring through the hoistway

- Connecting the control system

- Installing electrical components like buttons, lights, and sensors

The control system is like the brain of the elevator. It manages how the elevator moves and makes everything work together. The wiring has to follow specific codes and standards to keep everyone safe and avoid electrical problems. It's important to connect the control system correctly so the elevator can run smoothly and safely.

Step 5: Final Assembly and Cosmetic Finishing

The elevator installation is almost done. The last steps are about putting together everything and making it look good. This includes adding doors to the elevator car and to each floor.

Making the elevator look nice is important. This can include:

- Putting on interior panels and finishes inside the elevator car

- Adding ceiling panels and lights

- Installing floors

The final assembly makes sure all the parts work well together. This is a key stage for checking quality. The installation team goes over everything again. They make sure it meets all the specifications and safety standards.

Post-Installation Checklist

After you finish the installation, it is important to go through a detailed checklist. This will help make sure the elevator works well and follows all the safety regulations.

The checklist often includes:

- Final safety inspections

- Testing every part

- Getting the needed certifications

These checks help confirm that the elevator runs safely and smoothly. This will lower any risks and keep passengers safe.

Conducting Safety Inspections and Compliance Checks

Before an elevator can start working, careful safety checks are very important. This stage includes detailed evaluations to make sure the elevator meets all safety standards and building codes.

A qualified inspector, who is often an outside expert, usually does these checks. They carefully look at:

- The elevator's mechanical parts

- Electrical systems

- Safety features

Making sure everything meets high safety standards keeps passengers safe and protects building owners from possible problems.

Testing Elevator Functions and Emergency Systems

The elevator goes through plenty of tests to check how well it works and how safe it is in different situations. This testing looks at the elevator's:

- Mechanical functions

- Electrical systems

- Emergency procedures

The goal of this testing is to find any possible problems or mistakes. It is important to fix them before the elevator starts regular use.

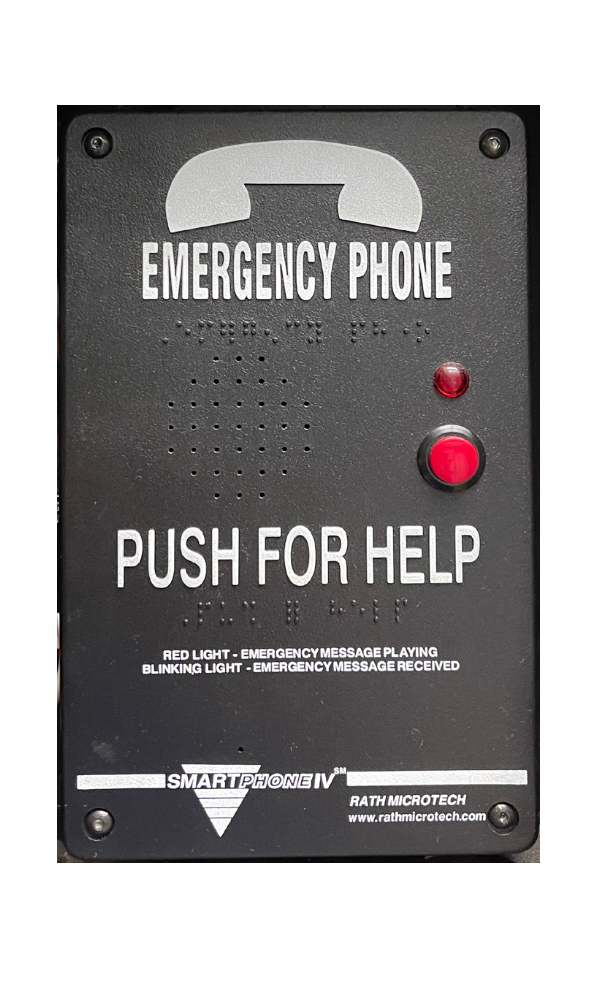

Keeping safety compliance as the top priority is crucial during this time. The tests also check if emergency systems work well, like:

- Emergency brakes

- Alarm systems

- Communication devices

Conclusion

The installation of elevators is very important for the safety and function of today’s buildings. It’s key to know the main parts, needed permits, and a clear step-by-step plan for a good installation. Also, after installation, checks for safety, compliance, and testing emergency systems are crucial for the elevator to work well. By sticking to the guidelines, picking the right type of elevator, and following the rules, you can improve the experience of using the building. Elevators are key for accessibility and ease, making them an important part of modern design. For more details on elevator installation and maintenance, check out our complete guide or contact us for help.

Frequently Asked Questions

What is the average time required for elevator installation?

The time it takes to install an elevator can change based on certain needs and rules. Building codes, the type of elevator, and safety features matter a lot. Other things, like how many floors there are, also affect the installation process.

How do I choose the right type of elevator for my building?

Choosing the right type of elevator involves different factors. These include the design of the building, your specific needs, the available space, and your budget. It is a good idea to talk with elevator experts during the design phase. They can help you find the best option for your situation.

What are the most common regulations affecting elevator installation?

Elevator installations need to follow strict safety rules and local codes. You must think about building codes, fire safety standards, and accessibility requirements. These are important when you need to get necessary permits and certifications.

Can elevator installation affect building operations?

Elevator installation might disturb building operations for a short time. This can be hard for tenants. Still, we can reduce these issues. It's important to communicate clearly, give people alternative routes, and plan the work for times when it's less busy. Taking these precautions can help everyone.

How often does an elevator need maintenance post-installation?

Regular maintenance is important. It helps keep the elevator safe and working well. You should do routine inspections, lubricate parts, and adjust components according to what the manufacturer suggests. Follow a set maintenance schedule to make sure everything stays in good condition.