How Much Does an Escalator Cost to Install and Maintain?

Key Highlights

- Escalator costs depend on factors like size, features, installation complexity, and location.

- Installation costs for commercial escalators range from $100,000 to $500,000 or more.

- Residential escalators typically cost between $40,000 to over $100,000 for installation.

- Annual maintenance costs vary from $3,000 to $12,000 for commercial and $1,000 to $5,000 for residential.

- Energy efficiency features can offset operational costs in the long run.

Introduction

In today's buildings, escalators are important for easy movement between floors. Before buying an escalator, it is key to understand its cost. This guide will help you know what affects escalator price. It offers valuable insights into the cost of an escalator, from installing it to keeping it running. When figuring out the cost, think about the scale, type, features, complexity of installation, and where it will go. Be ready for a substantial investment, as the price can change a lot based on your specific needs.

Understanding Escalators: A Primer

Escalators are a great invention that makes it easy to move between floors. Unlike elevators, which have a closed cabin, escalators have moving steps powered by a strong motor. This design lets many people use them at once. This is why they are perfect for busy places like shopping malls, airports, and transit stations.

Escalators are not only efficient but also accessible. They are made for different needs, including those who have trouble with mobility. Escalators offer a handy option compared to regular stairs. This improves the flow and accessibility in a building.

Definition and Basic Functionality

An escalator is a moving staircase. It helps people go between floors quickly. This good idea means you don't have to work hard and can easily get to different levels in a building. The steps are powered by an electric motor. They move along a track and stay flat, so you have a smooth ride.

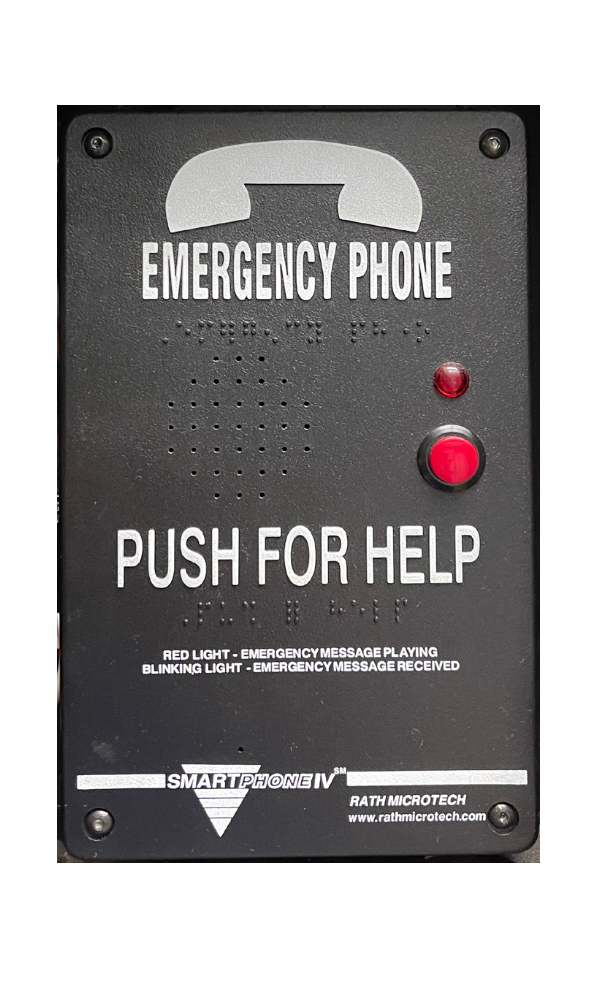

Safety features are very important in escalator design. There are emergency stop buttons at the top and bottom of the escalator. These buttons can stop the escalator right away if needed. Handrails move with the steps. They give you support and help you keep your balance. Skirt brushes are near the steps. They stop you from putting your feet or things too close to the edges, reducing the risk of accidents.

Escalators are often seen in stores or malls, but they are becoming popular in homes too. This is especially true for homes with many levels. Home escalators are designed well and offer a nice option to regular stairs. They make it easier to move around and add a touch of luxury to the house.

The Evolution of Escalators Over Time

Escalators started as simple rides in amusement parks. Now, they are everywhere in modern buildings, showing how much they have changed. Early escalators were basic and needed people to work them. Today, we have advanced, automatic escalators.

The design of escalators has greatly improved over the years. There are now different types of escalators made for specific needs and places. Escalator manufacturers keep updating their designs with new technology. This makes escalators safer, more efficient, and nicer to look at.

Today, escalators are a key part of cities around the world. They move millions of people every day with ease. As technology grows, we can expect even better and more eco-friendly escalator designs in the future for moving up and down.

Types of Escalators and Their Uses

Escalators come in different types. Each one is designed for specific uses. Knowing these differences is important when picking the best system for you. You should consider things like how many people will use it, the space you have, the building's design, and its main purpose.

For a busy place with lots of foot traffic, or for homes that care about easy access and looks, it's important to choose the right type of escalator. This can help improve how it works, ensure safety, and make it last longer.

Parallel vs. Crisscross: Choosing the Right Type

When we look at types of escalators, there are two main designs: parallel and crisscross.

Parallel escalators run next to each other and allow people to move up and down separately. This setup is great for a lot of people. It helps keep traffic flowing smoothly in both directions.

Crisscross escalators are arranged in an X shape. One escalator goes up while the other comes down. These look good but are not as effective for busy areas. They are often used for their looks or in places where there isn't much room.

Choosing between parallel and crisscross escalators depends on how they will be used and how many people will be using them. Parallel escalators are often used in busy places like shopping malls and airports because they help manage crowds better. In contrast, crisscross escalators may be chosen for certain building designs or places where space constraints are a factor.

Factors Determining the Type of Escalator Needed

Choosing the right type of escalator is not just about picking between parallel and crisscross designs. There are many factors to think about. It's important to look at the specific needs of the building first. Think about how the escalator will be used, how many people will use it, and any space constraints.

Foot traffic is very important when deciding on the escalator's width and capacity. In busy areas, you need wider escalators to fit more people and prevent crowding. At the same time, space limits can help decide if a parallel or crisscross design works better. This can also affect the escalator's length and rise.

Don't forget about the building's design and look. It's crucial to find a balance between what works well, how people move through the space, and how the escalator looks. This way, the escalator will fit in with the style of the whole building.

Preparing for Escalator Installation

Installing an escalator is a detailed job that needs careful planning and teamwork. It is important to involve skilled experts to make sure the installation goes smoothly and follows safety regulations. Before starting, you should fully check the site where the escalator will be placed.

This check should look at the building’s structure to ensure it can hold the escalator's weight and any moving loads. Think about how equipment will be delivered and make sure that utilities like electricity are ready and available.

Necessary Equipment and Resources

The installation process needs special tools and trained workers. Cranes are usually needed to lift and put in place the heavy escalator components. Welding tools are also important for putting the structure together. Skilled technicians who know electrical work, mechanical assembly, and safety rules are key to a successful installation.

Following safety standards is very important during the whole process. This means giving safety gear to the installation staff, setting clear safety rules, and doing regular safety checks. If safety is ignored, it can cause accidents, delays, and higher costs.

Make sure you have all the necessary permits and documents before starting the installation. You must follow local building codes and safety regulations. Ignoring these can lead to expensive delays and problems with the project.

Evaluating Installation Space Requirements

Before starting the installation process, it is very important to do a thorough site assessment. This assessment looks at the area where the escalator will go. It checks things like the height between floors, space for the escalator run, and the position of support beams and other building parts.

Some structural modifications might be needed for the escalator. This could include strengthening the floor to carry the weight or making openings between floors. These changes need careful planning and work to keep the building safe and follow the building codes.

It’s a good idea to hire a qualified structural engineer during this time. The engineer will check the current structure. They will see if the installation can work and suggest any changes needed for the escalator to fit well and work safely in the building.

Step-by-Step Guide to Escalator Installation

Installing an escalator is a detailed process that requires careful planning and skilled work. This guide gives a broad look at the usual installation steps. Remember, the exact steps may change based on the type of escalator, the site conditions, and the local regulations.

Always talk to a qualified escalator installer. They are important for making sure the installation is safe and goes well. Their knowledge helps in managing the project's details and following all relevant codes and regulations.

Step 1: Design and Planning

The first step in installing an escalator is to plan the design carefully. The installation team works closely with architects, engineers, and the escalator manufacturer. Together, they create detailed blueprints and specifications. These plans cover everything about the escalator design, such as sizes, materials, finishes, and safety features based on the specific requirements of the project.

When finalizing the escalator design, think about how it matches the overall look of the building. Choose materials and finishes that go well with the nearby environment. This helps to make the building look good and improves the experience for users.

It is very important to take accurate measurements at this stage. You need to figure out the vertical rise, the space for the escalator, and any things that might get in the way. These measurements will help shape the escalator design and ensure it fits well into the existing structure.

Step 2: Site Preparation and Safety Measures

Once the design is set, it's time to prepare the site. This means clearing the space where the escalator will go. You will need enough room to move tools and set up equipment. Depending on how big the project is, you might have to tear down old structures, change utility lines, or strengthen the floor to support the weight of the escalator.

It's very important to follow strict safety rules during the site preparation and the whole installation process. Set up clear safety rules, give proper safety gear to all workers, and check for safety regularly to reduce risks. Safety must come first at every step.

Before the escalator parts arrive, make sure the work area is safe. This can include putting up temporary barriers to stop unauthorized people from entering, making sure there is enough light, and clearly marking any dangers in the work area.

Step 3: Installation Process

With the site ready, the installation of the escalator can start. This stage usually includes delivering pre-made parts like the truss, steps, handrails, and electrical systems. Skilled workers carefully put these parts together. They follow the manufacturer's guidelines and stick to strong safety rules.

An important part of the installation is setting up the machine room. This special area holds the escalator's motor, drive system, and control panel. It needs proper ventilation, lighting, and safety features. Make sure the machine room is easy to access for maintenance and checks.

During the installation, major quality checks are very important. These checks help make sure everything is put in place right and works well. This means testing the escalator's moving parts, electrical systems, and safety features to ensure it is safe and ready to use.

Step 4: Inspection and Compliance with Regulations

Before an escalator can be used, it needs to pass several checks. These checks ensure it meets all local rules and safety standards. Qualified inspectors, usually from independent groups, carefully look at every part of the escalator. They check if it is strong, if the electrical systems are safe, and if all safety features work well.

Inspectors focus on important parts such as the speed and alignment of the handrails, the gap between steps and skirts, and how well the emergency stop buttons work. If any problems are found, they have to be fixed quickly so that the escalator is safe.

Once all inspections are done and any issues have been solved, the right authorities give the necessary permits and certifications. This means the escalator is safe for people to use. This last step shows that the installation process was successful.

Ongoing Maintenance and Safety Protocols

After your escalator is installed and running, it is very important to keep up with regular maintenance. This helps it last longer and keeps users safe. Maintenance includes checking it regularly, cleaning, adding grease, making small adjustments, and changing worn-out parts on time.

You should create a clear maintenance plan with a good service provider. The plan should specify how often to do inspections, what routine maintenance tasks to complete, and what to do for emergency repairs. This way, you can quickly and effectively fix any problems that come up.

Regular Maintenance Schedule

Establishing a regular maintenance schedule is important. It helps keep your escalator in good working order and safe to use. This schedule should include different tasks that happen at various times. Some tasks focus on immediate needs, while others are about long-term care.

Daily or weekly checks should include looking for debris, strange noises, or signs of wear and tear. Cleaning tasks, like removing debris from the steps and tracks and lubricating moving parts, will help avoid wear and keep things running smoothly.

More detailed maintenance, such as adjusting chain tension, checking electrical parts, and testing safety features, can be done monthly or quarterly. A complete maintenance plan helps the escalator last longer, reduces downtime, and makes a safe environment for everyone.

Emergency Repairs and Safety Checks

Regular maintenance helps lower the chance of surprise problems. Still, it's very important to have plans in place for emergency repairs. Escalators, like any machine, can break down suddenly. This demands immediate care to avoid inconvenience for users and stop any possible accidents.

It's key to have a main person to contact for emergency repairs. Make sure your maintenance provider is available 24/7 to handle urgent problems quickly. Frequently test emergency stop buttons and safety features to check that they work well in an emergency.

Teach your staff about the basics of escalator safety. They should know how to spot potential hazards and respond correctly. Having a trained team nearby can help manage sudden issues and reduce risks to users effectively.

Cost Analysis: Installation and Maintenance

Understanding the costs for escalator installation and maintenance is very important. These costs can change a lot based on the size, type, features, and how complex the installation is. When planning your budget, you need to include both the initial installation costs and the regular maintenance expenses.

Getting detailed quotes from trusted escalator manufacturers and installers is a good way to understand the overall cost. You should also think about energy efficiency. Choosing escalators with energy-saving features can help you save money on your energy bills in the long run.

Initial Installation Costs

Initial costs are important when you decide to install an escalator. These costs include several factors. First, there is the cost of the escalator itself, which can change a lot based on its size, length, materials, and features. You will pay more for custom designs, upscale finishes, and extra safety features.

The installation process adds to the total cost. Site preparation, building changes, and how hard it is to fit the escalator into the current building will affect the labor and materials needed. Local regulations and permit fees can also change the final price.

To have a clear idea of the installation costs, get detailed quotes from trusted escalator manufacturers and installation contractors. Be ready for a big investment, especially for larger projects or ones that need complex changes to fit in existing structures.

Annual Maintenance Expenses

Annual maintenance expenses are a crucial aspect of owning and operating an escalator. These expenses include routine inspections, cleaning, lubrication, and adjustments to ensure the escalator's safe and efficient operation. Neglecting regular maintenance can lead to increased wear and tear, potentially resulting in costly repairs and downtime.

Emergency repair costs can vary significantly depending on the severity of the issue. While regular maintenance mitigates the risk of major breakdowns, unforeseen issues can occur, requiring immediate attention. The table highlights the importance of budgeting for these potential expenses.

Additionally, energy consumption should be considered. Modern escalators often feature energy-saving technologies, such as variable frequency drives, that can reduce electricity costs over time. Factor in the escalator's energy efficiency when assessing the long-term operational expenses.

Conclusion

In conclusion, it is important for businesses and property owners to understand the costs and maintenance needs of escalators. Choosing the right type and ensuring proper installation are key. Regular maintenance is also essential to keep escalators safe and working well. By investing in good installation and following maintenance schedules, you can extend the life of escalators and lower unexpected repair costs. Stay informed about the different types, costs, and maintenance methods. This will help you make good decisions that fit your budget and needs. Always prioritize safety and functionality to provide a smooth experience for users.

Frequently Asked Questions

How much does a standard escalator installation cost?

The installation costs for a standard escalator can change a lot. This depends on the size, features, and how complicated the installation is. On average, you can expect the price range to be between $75,000 and $150,000 or even higher.

What are the biggest factors that affect escalator price?

Many things can affect escalator price. Some of the big ones are the escalator’s height, length, materials, features, how hard it is to install, and local regulations.

Are there significant differences in maintenance costs between types of escalators?

Yes, different types of escalators can have different maintenance costs. Bigger, more complicated, or busier escalators usually need more care. This means the overall costs can be higher.

How often do escalators need professional maintenance?

To meet safety standards and keep escalators working well, they usually need a professional check at least once a month. It's often suggested to have more detailed inspections and preventive maintenance every three to six months.

Can older escalators be upgraded or should they be replaced?

Older escalators can be improved by adding new parts or technology. This could include energy-efficient motors or better safety features. But if the escalator is close to the end of its life or needs many repairs, getting a new one may save money in the long run.